🆕 Release 26-04

Overview

Release 26-04 introduces a set of targeted improvements designed to increase data reliability, improve mobile usability, and enhance visibility across maintenance, packing, production, quality, and user management workflows.

These updates focus on reducing operational friction and ensuring that critical production data remains accurate and actionable, even in real-world conditions such as offline devices.

🔧 1. Close Maintenance Requests via Mobile QR Scan

Use Case

As a Maintenance Supervisor, you can now close maintenance requests directly from your mobile device by scanning a machine’s QR code — even if the production device is offline.

This ensures that:

-

Maintenance response time

-

Maintenance resolution actions

are always recorded accurately and on time.

How It Works

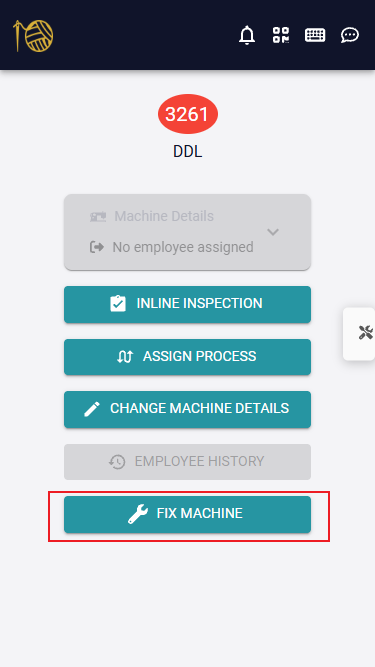

When a maintenance supervisor scans a machine QR code using the Garment IO mobile web app:

-

The system identifies the Machine ID from the QR code.

-

The machine details page opens (same as the standard QR scan view).

If:

-

Machine status = Stopped

-

The user has maintenance permissions

-

-

A new action button appears:

Button: Fix Machine

Fix Machine Flow

When the supervisor clicks Fix Machine:

-

The action behaves as if the supervisor scanned their RFID tag

-

Maintenance response time is recorded

-

The maintenance ticket status changes to Under Inspection

-

The user is redirected (same tab) to the Maintenance Request Details page

Available actions:

-

🔧 Repair Machine

-

🔁 Replace Machine

-

❌ False Alarm

Once the action is saved:

-

The maintenance request is closed

-

A resolution timestamp is recorded

🏷️ 2. Faster RFID Tag Assignment at Assigning Tags Station

The Assigning Tags Station has been optimized to significantly speed up RFID assignment.

New improvements include:

-

Displaying batch group details and group type (Bundle or Stack)

-

Allowing users to define the number of RFID tags per batch

-

Prioritizing batches that do not have all RFID tags assigned

-

Ability to expand and edit RFID tags on already-assigned batches

Sequential Assignment

Users can now click Assign Sequentially, which:

-

Starts from the first unassigned batch

-

Enables fast, continuous scanning of RFID tags without manual selection

🎯 3. Live Floor Cards Based on Targets (P2P) Instead of Efficiency

Live floor displays can now change colors based on Plan-to-Performance (P2P) instead of efficiency.

How P2P Works

-

Performance is calculated against the expected target for elapsed time

-

Example: If only 80 minutes have passed in the day, the system evaluates output against the target for those 80 minutes

-

The card color reflects whether the worker is ahead, on target, or behind

Configuration

Factories can:

-

Control P2P thresholds and color codes from Factory Settings

-

Choose per display whether cards are based on Target (P2P) or Efficiency

📦 4. Packing Details Added to PO Report

If the Packing Module is enabled, the Production Order (PO) Report now includes detailed packing insights.

New Data Points

Assortments

-

Value: Number of unique assortments in the order

-

Click → Opens assortments list filtered by this order

Boxes Breakdown

-

Fully Filled Boxes → Status = Filled

-

Partially Closed Boxes

-

Partially Open Boxes

-

Each value is clickable and opens the filtered box list

Additional Packing Insights

-

Daily packed pieces

-

Packed vs other stages comparison per color and size

These enhancements help identify delays and bottlenecks more precisely.

📊 5. Packed Pieces Card on Dashboard

A new Packed Pieces card has been added to the Dashboard, displayed alongside Inspected Pieces.

This allows managers to:

-

Instantly compare packing vs inspection output

-

Detect downstream bottlenecks faster

📦 6. View Box History Timeline

Users can now open the history timeline for any box to view:

-

All box filling events

-

Who performed each action

-

When it happened

-

Which workstation was used

This adds full traceability to packing operations.

📑 7. New Order Status Report (Production Module)

A new Order Status Report has been added to the Production Module.

Users can:

-

Select an order

-

View the status of each color–size combination inside the order

This provides a clear picture of completion progress at a granular level.

🧾 8. More Information in Batch & Batch Group Headers

Batch and batch group headers now display:

-

RFID tags

-

Color shade

From the history page:

-

Authorized users can add or edit RFID tags

-

Improves traceability and correction workflows

📉 9. Wasted Reports Header Enhancements

The Wasted Reports header has been improved:

-

Users can choose to display tiles by Total or Average

Tiles now show:

-

Number of workers who arrived late

-

Number of workers who left early

-

This removes the need to manually count records from tables.

⚙️ 10. Additional System Enhancements

🧑💼 User Management

All user changes are now logged in User Logs, including:

-

Language

-

Role

-

Homepage

-

Scope

-

Other profile updates

-

-

Full visibility into who changed what and when

💰 Bulk Salary Updates

-

Salaries can now be updated in bulk from the Users page

🧪 Quality Supervisor Performance Report

New column added before Batch Inspection Duration:

-

Piece Inspection Duration

-

-

Improves inspection efficiency analysis at the piece level

📈 Report Navigation Improvements

In Process Throughput Report and Standard Process Report:

-

Clicking an employee’s name opens their Employee History Report

✅ Summary

Release 26-04 delivers:

-

📱 Mobile-first maintenance resolution

-

🏷️ Faster RFID assignment workflows

-

🎯 Target-based live floor visibility

-

📦 Deeper packing traceability

-

📊 Stronger reporting and navigation

-

🧾 Improved auditability and transparency

All improvements are designed to keep your production data accurate, connected, and actionable, even in complex factory environments.

Related Articles

🆕 Release 25-42

Overview In this release (Version 25-42), we’re introducing several quality-of-life improvements across the system based on valuable feedback from our partner factories. These updates aim to make daily operations faster, more connected, and easier to ...🆕 Release 25-46 – New Reports, Smarter Packing, and More Control!

Overview We’re excited to announce Release 25-46, which introduces several system improvements designed to make your daily operations smoother, faster, and more insightful. From new analytical reports to smarter packing tools and better production ...🆕 Release 25-47 – New Reports, New Insights, and CMN Support!

Overview We’re excited to introduce Release 25-47, packed with powerful new reporting tools and an important time-unit enhancement for Moroccan factories. This update brings more transparency to packing performance, deeper financial insights, and ...Introducing the Packing Module in Garment IO

Overview We are proud to introduce the Packing Module — a new addition to the Garment IO Production System designed to help factories organize and monitor the final step of production with better accuracy, accountability, and visibility. The Packing ...🆕 Multi-Style Cutting Module

Overview We’re thrilled to introduce the Multi-Style Cutting Module, a major enhancement to the Cutting Module that brings greater efficiency, flexibility, and control to the cutting process. This feature allows cutting specialists to: Add markers ...